Download: pdf

Seeking a full time position after December 2021.

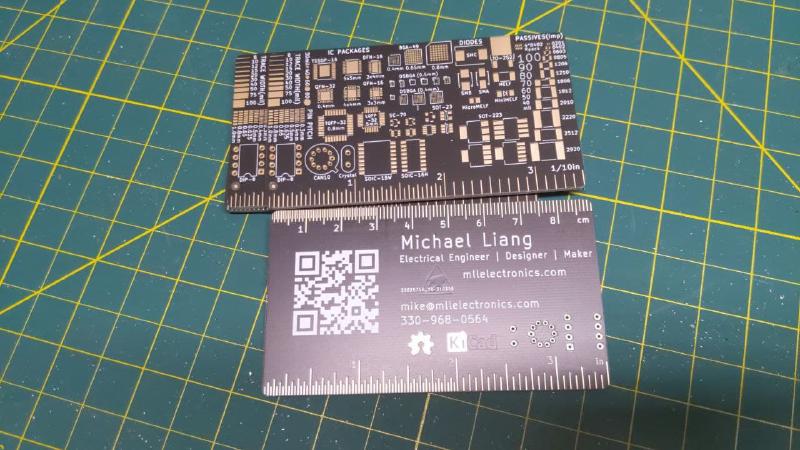

Michael Liang

Skills

- Rapid Prototyping

- PCB Design (KiCAD, Eagle)

- 2D CAD (AutoCAD, NanoCAD)

- 3D CAD (SolidWorks, Fusion 360)

- Soldering (SMT rework, through-hole)

- 3D Printing and Additive manufacturing

- LabView

- MATLAB

- Microcontrollers (STM32, AVR/Atmel, PIC)

- Programming (C, Python)

Professional Experience

ELECTRICAL ENGINEERING CO-OP, Toast Inc, Boston MA, Jun 2021 - August 2021

- Designed and implemented an automated robotic hardware testing platform for Toast Hardware products. Also worked closely with cross disciplinary team of engineers to create detailed specifications for a upcoming tablet device.

- Gained experience in understanding the complexity of hardware design with multiple high speed signals such as MIPI, LVDS, gigabit ethernet and USB C.

- Collaborated with ODM/JDM manufacturing vendors through out the product development lifecycle.

- Technologies Utilized: ESP32, Python, Fusion 360, RF Explorer, and PADs viewer.

ELECTRICAL ENGINEERING CO-OP, WARDJet, Tallamadge OH, May 2020 - May 2021

- Designed and implemented multiple data collection and analysis systems to assist with root cause analysis of clogs in cutting operations.

- Utilized metrics from sensors such as accelerometers, moisture sensors and piezoelectric microphones to assist with product development road map.

- Technologies Utilized: Python, Digital Signal Processing,Raspberry Pi, and MATLAB.

UNIVERISITY OF AKRON UNDERGRADUTE RESEARCH, LTA Research & Exploration, Akron Ohio, Sep 2018 - March 2019

- Worked closely with a multidisciplinary team to develop custom rapid prototyping and fabrication solutions for a innovative Unmanned Aircraft System.

- Retrofitted new safety equipment, maintained, and calibrated a 300 watt industrial laser cutter.

- Maintained a print farm of over 15 industrial grade 3d printers which ran 24/7.

- Technologies Utilized: SolidWorks 2018, Simplify3D, Octoprint, and RDWorks laser controller software.

SUMMIT COUNTY ENGINEER’S OFFICE, Engineering Intern, Akron Ohio, Jul 2018 - Sep 2018

- Assisted with drafting of plans in AutoCAD and learned industry standard engineering draw practices.

- Technologies Used: AutoCAD Civil 3D 2013, ArcGIS (mapping software)

Projects

Keyboard Warrior: A custom built STM32F303 keyboard running the QMK firmware.

- Goal: design and make a modular mechanical keyboard with ability to extend functionality over i2c (number pad, OLED display, etc)

- Schematic and board routing was done in KiCAD. With attention paid to crystal oscillator design, USB differential pair layout, and power supply design.

- Mechanical design was done in SolidWorks. A custom stacked aluminum case design was chosen due to simplicity and ability to easily fabricate.

LMS3990 CNC Conversion: A custom CNC Mill

- Electronics consist of Mach 3 breakout board, custom high current stepper drivers based on TMC5160 driver with encoder feedback, and a spindle speed controller.

- Mechanically designed in SolidWorks. Converted from linear lead screws to a C7 grade ballscrew system with custom made motor mounts.

HAkron Public Relations Officer: Akron’s Official College Hackathon Group

- Worked on expanding and engaging with engineering student organizations on campus in order to teach basic programming and electronics.

- Hosted HAkron 4K a hackathon which is a 24 hour invention marathon that encourages creativity, innovation, learning and engineering.

- Worked closely with a team to manage 80+ students and lead the electronics hardware team. Mentored several teams, organized access to the Bounce Innovation hub makerspace, and gained experience in teaching troubleshooting to non-technical individuals.